How to Do Usual Lawn Sprinkler Fixing to Maintain Your Irrigation System

Problems such as reduced water stress, blocked nozzles, and busted heads can dramatically impact the system's efficiency. Cleansing or unclogging nozzles and changing malfunctioning heads are fundamental jobs that can boost water distribution. Adjusting water stress to the ideal variety of 30-50 psi ensures uniform coverage.

Identifying Common Sprinkler Issues

A properly maintained sprinkler system is important for reliable lawn treatment, however also the ideal systems can encounter issues. One constant problem is low water pressure, which can trigger unequal watering and completely dry spots on your lawn.

Another prevalent issue is lawn sprinkler heads that do not stand out up or withdraw properly. This breakdown could be due to debris obstructing the system or a worn-out springtime. In addition, misaligned sprinkler heads can cause water being sprayed onto sidewalks, driveways, or other unintentional areas, bring about water waste and inadequate coverage of your yard.

Cleaning and Unclogging Nozzles

When managing typical lawn sprinkler issues, dealing with clogs is critical for keeping ideal system performance. With time, debris such as dirt, grass cuttings, and natural resource can gather within the nozzles, blocking water flow and decreasing irrigation effectiveness. To ensure your sprinklers operate properly, normal cleaning and unclogging of nozzles is necessary.

Begin by turning off the watering system to avoid any unintentional water discharge. Meticulously eliminate the nozzle from the sprinkler head. For comprehensive cleaning, soak the nozzle in a combination of water and vinegar or a commercial cleansing solution made to liquify mineral deposits.

Wash the nozzle under running water to get rid of any type of continuing to be debris and reattach it to the lawn sprinkler head. Turn the system back on and observe the water distribution to make sure the blockage has actually been cleared. Regular upkeep of sprinkler nozzles can substantially boost the long life and performance of your irrigation system.

Changing Broken Lawn Sprinkler Heads

Replacing damaged lawn sprinkler heads is an essential step in maintaining an effective irrigation system. When a lawn sprinkler head ends up being damaged, it can bring about water wastage and unequal insurance coverage, which can negatively impact the wellness of your lawn or garden. elevated sprinkler The primary step is to determine the malfunctioning head, typically evident via irregular water spray patterns or water merging around the base.

Begin by shutting off the supply of water to avoid any kind of unneeded splilling. Utilize a shovel to meticulously dig around the lawn sprinkler head, ensuring you do not damage the bordering piping. When exposed, unscrew the busted head from the riser, taking note of the make and design to guarantee you acquire a compatible substitute.

Screw the brand-new lawn sprinkler head onto the riser by hand, guaranteeing it is snug but not excessively tight to prevent damaging the threads. Transform the water supply back on and evaluate the brand-new head to ensure it is functioning correctly, making changes as needed.

Changing Water Pressure and Protection

In order to optimize the performance of your watering system, changing water stress and insurance coverage is crucial. Correct water stress guarantees that each sprinkler head runs efficiently, dispersing water equally throughout your lawn or garden.

Next, concentrate on changing lawn sprinkler head insurance coverage to remove dry places and overwatered areas. Begin by switching on the system and observing the spray patterns. For rotating heads, readjust the arc and distance setups using a screwdriver to customize the direction and distance of check out this site water circulation. For spray heads, use the modification screw on the top to tweak the spray pattern.

Ensure overlapping protection in between surrounding sprinkler heads to prevent missed out on locations. Likewise, check for any kind of obstructions such as plants or frameworks that might obstruct water circulation. By calibrating water stress and adjust sprinkler head coverage, you can maintain a rich, healthy and balanced landscape while saving water sources properly.

Regular Maintenance Idea

Next, examine for leakages in the irrigation lines. Little leaks can rise right into considerable problems if left unaddressed. Screen the water stress during procedure; fluctuations can show concealed leakages or obstructions. Change damaged or worn-out components immediately to prevent additional difficulties.

Readjust the system's timer setups according to seasonal water needs. Overwatering or underwatering can harm your landscape and waste sources. Additionally, evaluate the rainfall sensing unit and ensure it is operating correctly to avoid unnecessary watering during rainfall.

Conclusion

Dealing with typical issues such as low water pressure, blocked nozzles, and broken heads can dramatically improve system effectiveness. Cleaning nozzles with a great needle and vinegar, replacing damaged heads, and changing water pressure to 30-50 psi are vital actions.

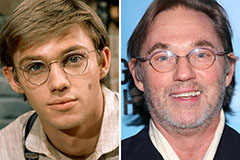

Rick Moranis Then & Now!

Rick Moranis Then & Now! Tony Danza Then & Now!

Tony Danza Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now!